Geotechnical Engineering For Construction Projects Fundamentals Explained

Geotechnical Engineering For Construction Projects Fundamentals Explained

Blog Article

The Basic Principles Of Geotechnical Engineering For Construction Projects

Table of ContentsLittle Known Facts About Geotechnical Engineering For Construction Projects.Some Known Incorrect Statements About Geotechnical Engineering For Construction Projects Not known Facts About Geotechnical Engineering For Construction ProjectsThe 6-Second Trick For Geotechnical Engineering For Construction ProjectsThe smart Trick of Geotechnical Engineering For Construction Projects That Nobody is Talking About

As a result, throughout the examination, it is crucial to pierce at the required depth and the required number of openings according to the recommendation of the Canadian Structure Design criterion. Occasionally, the owner might save some Geotechnical Investigation cost yet wind up spending even more than the expected throughout the construction price.The responsibilities of the geotechnical consultant include providing material testing for building and construction support. Geotechnical Engineering for Construction Projects. Geotechnical designers evaluate all the field examination records to make sure that building is going on according to the project spec. Throughout construction, a confirmatory test for soil compaction is done on-site to make sure that no future negotiation takes place

After the concrete is poured -7 days and 28 days- examinations are performed on concrete samples gathered from the site to guarantee that the concrete poured satisfies the style criterion. Asphalt core is taken after the Asphalt is laid and compressed to confirm that it meets the layout criterion. All lab test reports are evaluated by the Geotechnical Designer to make certain that it satisfies the project requirements.

How Geotechnical Engineering For Construction Projects can Save You Time, Stress, and Money.

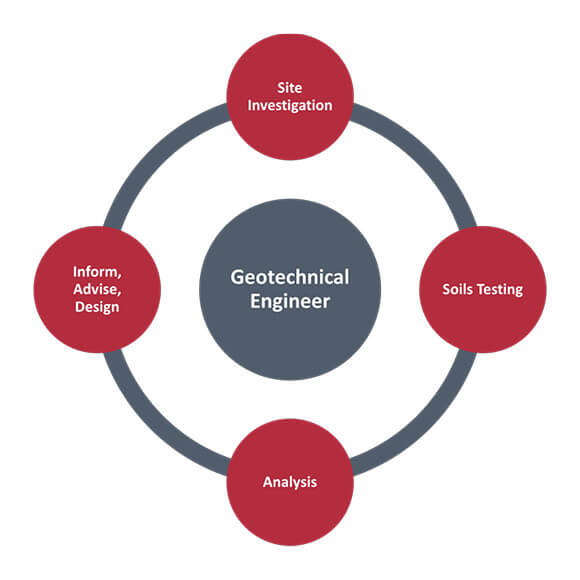

Geotechnical design plays a critical role in guaranteeing the stability of construction tasks. Geotechnical engineering is an essential branch of civil engineering that concentrates on recognizing the behavior of planet products, such as soil and rock.

For a reliable structure and a smooth building process, count on to offer the expertise you need. Get in touch with to obtain professional advice and geotechnical solutions customized to your next project.

Some Known Facts About Geotechnical Engineering For Construction Projects.

When starting a land development task, comprehending the ground underneath your feet is as critical as the frameworks you plan to build over it. Our Geotechnical Engineering group evaluate the ground, guaranteeing it appropriates for the recommended development while offering you with the details called for to meet your project goals.

Geotechnical Engineering takes a look at the development of the ground, as it is the foundation for all jobs. Where frameworks need to be designed relative to the ground problems; ground problems (e.g., soft ground) may require strengthening depending on the size of the intended structure. Before building, you require to find out about the groundwater, dirt framework, and liquefaction possibility of your land.

For websites that are not read this post here connected on the regional authority infrastructure added site investigations would certainly be called for to provide technical inputs for on-site stormwater and wastewater. We have actually experienced Geotechnical Engineers based in each office, supporting your geotechnical needs nationwide. Connect to us to go over just how we can support your next task.

These records are tailored to meet the certain demands of a project and consist of design criteria and recommendations for the building and construction of a variety of synthetic frameworks. As well as offering working as a consultant solutions covering areas such as slope stability and load-bearing capacities for various products, these designers take on r & d tasks to improve approaches, equipment, products understanding and evaluation covering whole lifecycles.

Some Known Questions About Geotechnical Engineering For Construction Projects.

Prices of pay generally raise as your understanding and abilities expand, with standards aiming to a graduate starting salary of in between 18,000 and 28,000 per year in the UK. This increases to 26,000 to 36,000 with a couple of years of experience and afterwards reaching 40,000 to 60,000+ for senior, legal or master designers.

However, with the ideal application it is feasible to master the occupation and gain entrance to a difficult yet satisfying and essential occupation. A rock hound would require to retrain to become a geotechnical designer, although there is plenty of cross-over between both occupations, which can make this simpler - Geotechnical Engineering for Construction Projects. Rock hounds require to have an understanding of dirts, rocks and various other materials from a clinical perspective, while geotechnical engineers tale their expertise of issues such as dirt and rock technician, geophysics and hydrology and apply them to engineering and ecological tasks

When beginning, these engineers will certainly have Related Site a tendency to service much less complicated jobs, developing up knowledge and experience ready for even more challenging work later. Geotechnical designers have a tendency to specialise in details locations as they grow in experience, focusing on specific facilities such as trains, roadways or water. These engineers likewise deal with eco-friendly energy, offshore and onshore oil and gas, nuclear power, and much more.

How Geotechnical Engineering For Construction Projects can Save You Time, Stress, and Money.

The time required to come to be a geotechnical designer depends on where you are based, where you study and what degree of education you intend to obtain before entering the office. Are you going to explore an apprenticeship, take an university level or deal with towards a Master's or PhD? However, generally-speaking it takes 3-4 years to reach the fundamental demands to begin a profession as a geotechnical engineer.

These procedures allow experts to evaluate a host of dirt technicians including weight, porosity, void-to-solid fragment proportion, leaks in the structure, compressibility, maximum shear toughness, bearing capacity and deformations. If the structure requires a deep structure, engineers will certainly utilize a cone infiltration examination to estimate the quantity of skin and end bearing resistance in the subsurface.

When analyzing a slope's balance of shear anxiety and shear strength, or its capability to endure and undertake movement, rotational slides and translational slides are typically thought about. Rotational slides fail along a bent surface, with translational slides taking place on a planar surface area. A professional's objective is to identify the conditions at which an incline failure can happen.

Usually, findings recommend that a site's dirt need to be dealt with to enhance its shear strength, rigidity and permeability prior to layout and construction. When it comes time to outline my response foundation plans, experts are significantly concentrated on sustainability, even more especially how to reduce a structure's carbon footprint. One tactic has been to replace 20 percent of a foundation's cement with fly ash, a waste item from coal fire nuclear power plant.

Report this page